Real-time measurements - Production according to specification - Treceability - Recall - Deviation

Quality monitoring

All businesses have their own quality standards and requirements. How a business chooses to ensure its quality is usually tied to its own quality plans and models. The work is often linked to working groups that manage and set requirements for the business.

There are significant differences in how this work can be done, and it is typically governed by the type of business.

For production industries, quality activities are related to setting detailed requirements for products, tolerances, and meeting customer and regulatory requirements for production.

In modern industry, it is increasingly possible to measure quality directly, online, in production on the product. However, it is also still necessary to take samples of a product and have it analyzed in a laboratory, or perform its own control measurements.

FieldTalk can integrate measurement systems, collect production data, and link the results to quality requirements and specifications.

The potential for automation is significant.

Example of critical quality data:

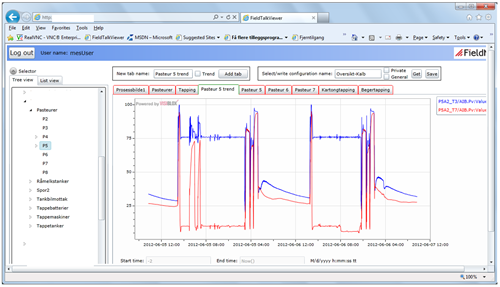

The image shows the temperature trend for a pasteurizer in milk production. There are regulatory requirements for how this should be done and how it should be documented.

Traditionally, physical printouts on paper have been used and stored in accordance with regulations. But digital display and documentation can ensure the same data. Furthermore, automatic inspection and reporting can simplify and improve compliance with the requirements.

Trend Pasteur

Live produksjon

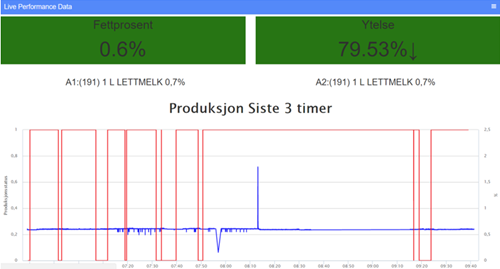

Example of online product analysis:

This shows the ongoing production of milk, where smart instrumentation can measure and calculate if the product is within the required specification for fat percentage.